Last post we talked about what we covet, which is what we see. Since high quality rooftop ductwork is rarely seen, it escapes our desire for it. Hannibal doesn’t let a little thing like being locked in a cell prevent him from having a vision of the world. He makes his own vision. Can you? We won’t go too far with the theme of Hannibal being a visionary thought leader, but he does have quite an imagination. Must be all the fava beans.

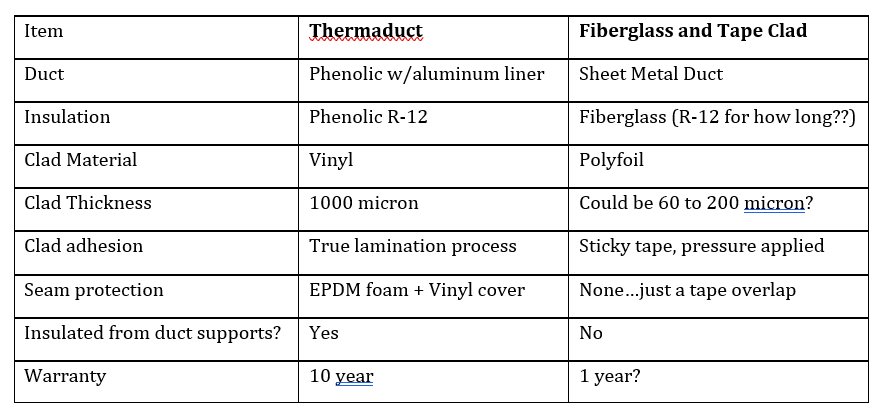

WHAT IS HAPPENING NOW: THERMADUCT COMPARISON TO MINIMUM STANDARD SMACNA GUIDELINES In other words, would you allow ductboard as a substitution to metal duct? No? Why not? Comparable difference here.

WHAT PRODUCTS WOULD HANNIBAL LECTER WRITE INTO A COMPETITIVE OUTDOOR DUCTWORK SPECIFICATION?

- Base Bid Thermaduct

- Alternate Bid Fabricated by the Contractor

-

- a. Sheet Metal ductwork per SMACNA, Seal class A.

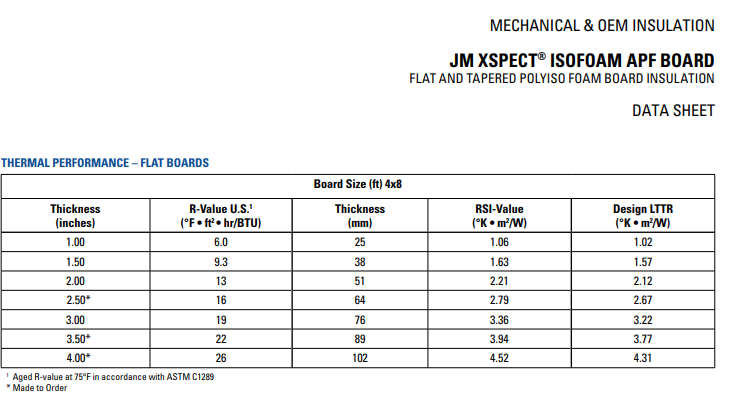

- b. Closed cell insulation only, R-Values per the chart below. Fiberglass gets wet, and when it’s wet it has no purpose. Hannibal always has a purpose.

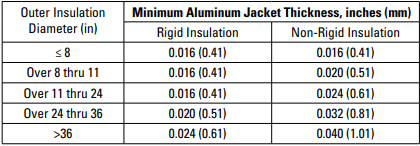

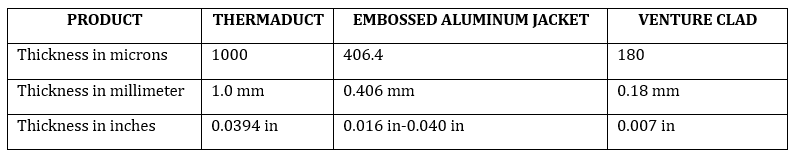

c. Jacket thickness should follow the Johns Manville guidelines below. Thermaduct cladding is 1000 microns thick, or 0.039 inches.

d. Venture Clad (peel and seal) not acceptable. It only has a thickness of 0.18mm, which is 1/5 the thickness of the casing of Thermaduct and less than half the minimum jacketing

3. Field inspect the ductwork, just so you know what it looks like!

4. Pressure test the ductwork, like the dang code says to!

-

All the best, Tom Gelin

Air Flow, Inc. 8355 W. Bradley Road Milwaukee, WI 53223

414-351-1999